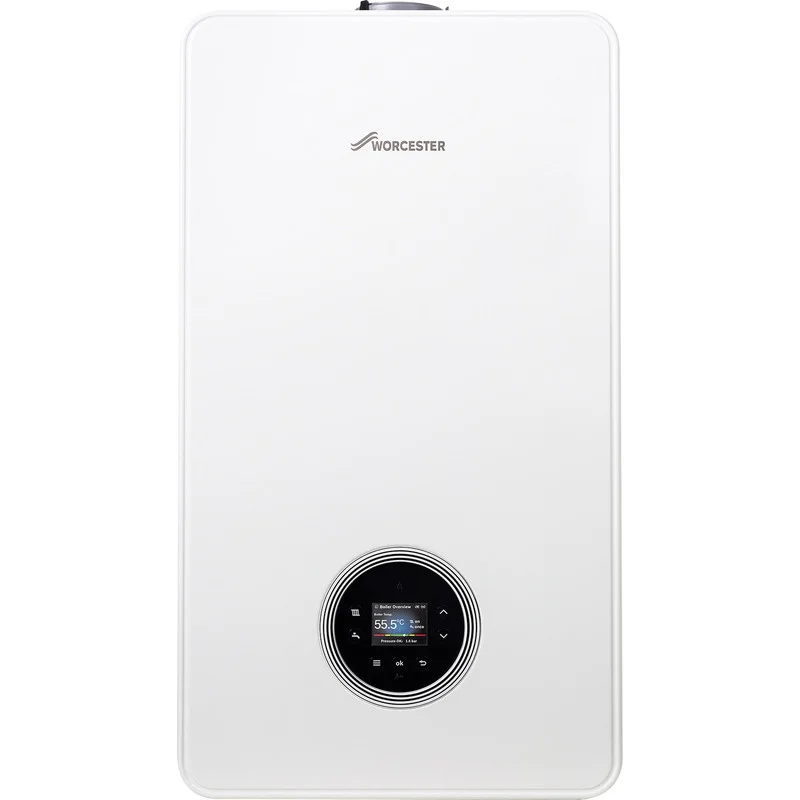

Purchase a Worcester Bosch boiler with installation included for seamless heating solutions. Benefit from expert installation services and enjoy reliable performance. Explore our range and find the perfect heating solution for your home today.

Explore the Master Gas London guide to Worcester Bosch boilers. Renowned for innovative technology and customer satisfaction, Worcester Bosch offers top-quality heating solutions. Discover key insights to make informed decisions for your heating needs.

Buy a Worcester with Installation from £2445. Up to 12 year parts and labour warranty included

Schedule a Worcester Boiler Repair from £108 with 'No Hourly Charges.' Book Today!

Service your Worcester boiler for £108. Ensure safety and efficiency. Book Today!

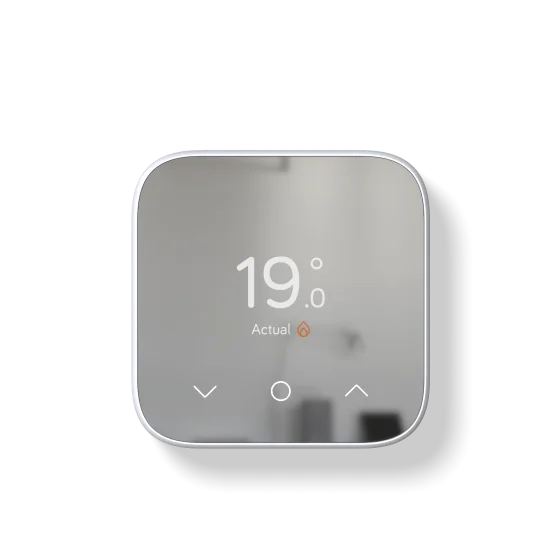

Enhance your Baxi boiler with a smart thermostat from £220. Optimize control and savings!

Since its founding in 1962, Worcester Bosch has led the heating industry with innovative and reliable products. Their mission prioritized performance, energy efficiency, and customer satisfaction. Introducing the first combination boiler in the 1970s, Worcester Bosch revolutionized home heating. With ISO 9001 certification, they maintain quality and reliability. Award-winning solutions and joining the Bosch Group in 1992 have further propelled their success, ensuring state-of-the-art heating products for homeowners worldwide.

Worcester Bosch is synonymous with home heating reliability. Their focus on craftsmanship and quality ensures each boiler is rigorously tested, offering long-lasting performance. Backed by industry-leading warranties and ISO 9001 certification, Worcester Bosch instills confidence in their products’ durability. Trusted by homeowners for decades, their reliability extends to dedicated customer support and accredited installers, ensuring a seamless experience.

Worcester Bosch leads in energy efficiency, offering cutting-edge solutions that reduce carbon emissions and lower utility costs. Through advanced technologies like high-efficiency condensing boilers and intelligent controls, Worcester Bosch maximizes energy usage while minimizing waste, ensuring both comfort and sustainability. Recognized by the Energy Saving Trust and fully compliant with ErP regulations, Worcester Bosch boilers guarantee exceptional efficiency and environmental performance. With reduced energy consumption and innovative heat exchanger technology, Worcester Bosch provides cost-effective and eco-friendly heating solutions for homeowners.

Worcester Bosch prioritizes safety in their heating systems with advanced features for homeowners’ peace of mind. Equipped with robust gas safety mechanisms, boilers include flame sensors, gas valves, and automatic shut-off systems to detect and address anomalies. Overheat protection, pressure relief valves, and flame failure detection ensure safe operation, while compliance with industry standards guarantees adherence to safety protocols, offering homeowners the safety assurance they need.

Investing in a Worcester Bosch boiler ensures not just a top-tier heating solution but also access to exceptional service and support. With expert technical assistance available at your fingertips, along with an extensive network of accredited installers, Worcester Bosch guarantees expert installation and troubleshooting. Plus, industry-leading warranty protection and the use of genuine Worcester Bosch parts ensure optimal performance and reliability throughout your boiler’s lifespan, providing you with peace of mind and satisfaction.

08/01/24

Tam and his team, great price, great installation , clean tidy, great after care. Most of all Nice people. Vaillant Ecotec Plus. Rad installed.In the words of Tina Turner “simply the best”

05/01/24

Installed a new boiler for us in 2022. New Year’s Eve 2023 we had an unrelated problem with our Co2 alarm, Ed called me, then came round to check everything was fine – fantastic service and we were so grateful!

12/11/23

We had a boiler replaced. The team were amazing from quotation to installation. The new boiler was installed in a day. The house was left tidier than when they arrived. Highly recommended.

03/01/24

19/10/23

Referred to this amazing company Master Gas London as l needed to replace an old boiler. I contacted them, in a couple of days, surveyed, detailed quote with recommendations, and installation arranged.

21/12/23

New boiler, replacement of leaking underfloor heating manifold, rerouting overflow pipe, improved piping in cellar – all completed to a high standard in one day. Thanks!

18/11/23

Highly recommend Master Gas for any boiler issues. They came and fitted a new boiler quickly and at a fair price & were a pleasure to have in the house. Highly recommend.

Worcester Bosch boilers are known for their durability and longevity. With proper installation and regular maintenance, they can last for 12 to 15 years or even longer.

Worcester Bosch boilers come with varying warranty periods, depending on the model and type. Typically, they offer warranties ranging from 5 to 12 years, providing peace of mind and protection for your investment.

Worcester Bosch boilers are designed with energy efficiency in mind. They incorporate advanced features, such as condensing technology and modulating burners, to maximize fuel efficiency and reduce energy consumption.

Yes, regular maintenance is essential to keep your Worcester Bosch boiler operating at its best. It is recommended to have annual servicing by a Gas Safe registered engineer to ensure optimal performance, efficiency, and safety.

Yes, Worcester Bosch offers a range of boilers that are compatible with smart home technology. These boilers can be integrated with smart thermostats and home automation systems, allowing you to control your heating remotely and optimize energy usage.

Worcester Bosch boilers prioritise energy efficiency, which contributes to their environmental friendliness. They are designed to minimize carbon emissions and reduce energy wastage, making them a greener heating solution.

Yes, Worcester Bosch offers a range of boilers that are compatible with renewable energy systems such as solar thermal panels and heat pumps. These options allow you to further reduce your carbon footprint and enhance energy efficiency.

Yes, Worcester Bosch boilers can provide both heating and hot water for your home. They are designed to efficiently deliver both functions, ensuring your comfort and convenience.